5/2023: First of several pending patents had all claims allowed!

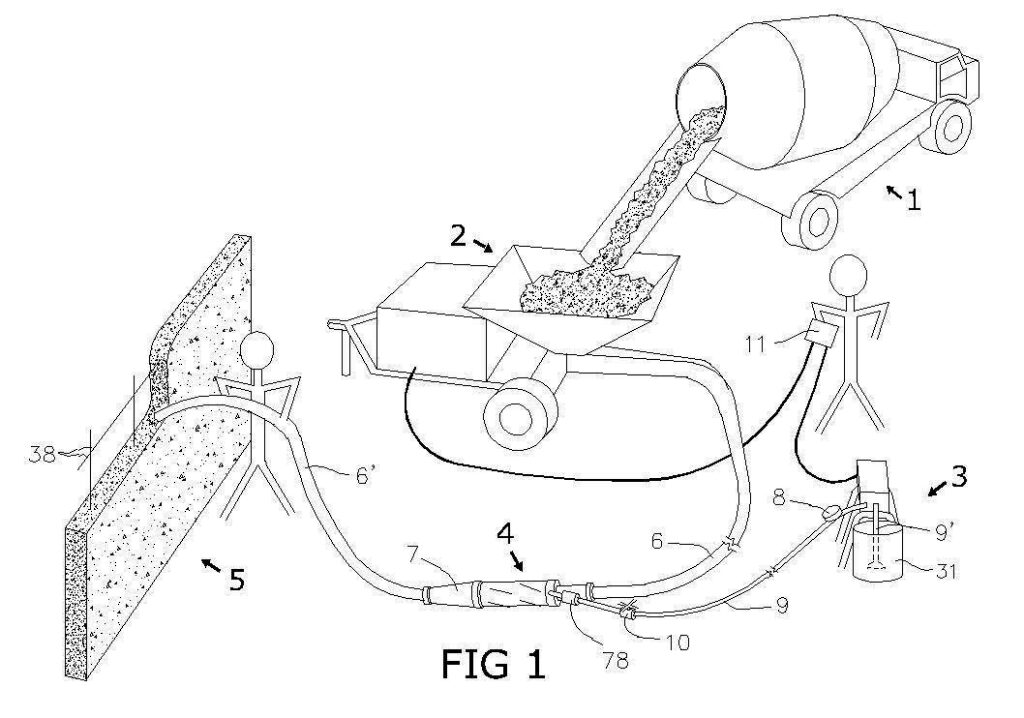

This page is organized by our main ideas. It gets more interesting as you scroll down. Specific patent information follows. These ideas may seem very ambitious, but our view is that machine-control placement of concrete is inevitable. We have developed very practical ways to do this – and these new ways can meet all existing building codes, using conventional materials and even existing equipment.

Spacecrete has not been funded by any outside source or obligation. All of the proprietary products, material, and IP development – including PCT and US/foreign patent applications – is unencumbered, and is under control of the original developer (SpaceCrete). Our intent is to change this.

Avoid burdens of venture capital: Bring these ideas directly to a well-established forward-looking construction business, allowing a low IP cost. This is also the most efficient way to develop new methods for profitable applications in construction markets. For our part, it’s not so much about money. Our main motivation is to see these ideas implemented.

The early admix formula made extremely workable concrete, but needed a higher dose.

3D-Admixtm Composition

This is a high-solids solution that provides properties to normal pumpable concrete, modifying it to allowing 3D printing and very rapid slip forming, etc, at an extremely low dose, typically injected into the concrete pump line. The admix simultaneously provides benefits of internal curing and plastic shrinkage prevention. This concept can also be used as a carrier to deliver water-reactive agents, particularly powders, into concrete or other water-based cement-binding systems, because the new unique admix composition does not allow these agents to react until coming in contact with more water. There are variations of the admix utilizing a higher dose and involving byproduct surplus materials – so as to enhance concrete workability at zero-slump; or by exploiting a volumetric mix processes rather than injection into a pumped line. These concepts are all disclosed in our first patent application. Subsequent improvements to the 3D-AdmixTM composition are presently treated as a trade secret.

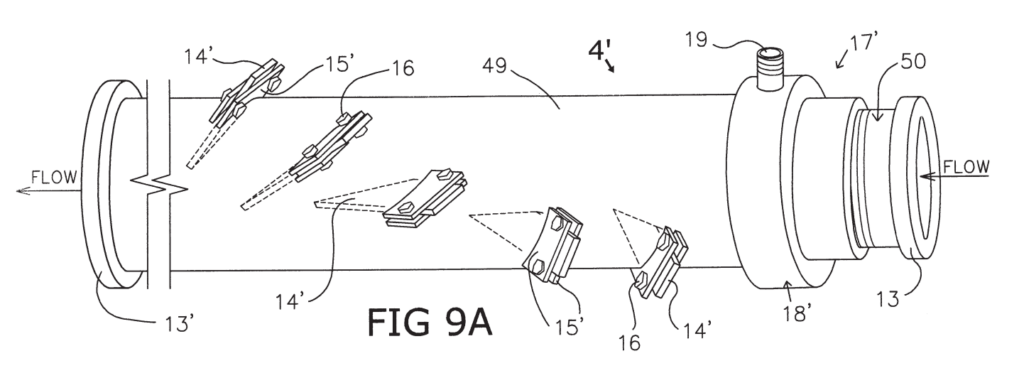

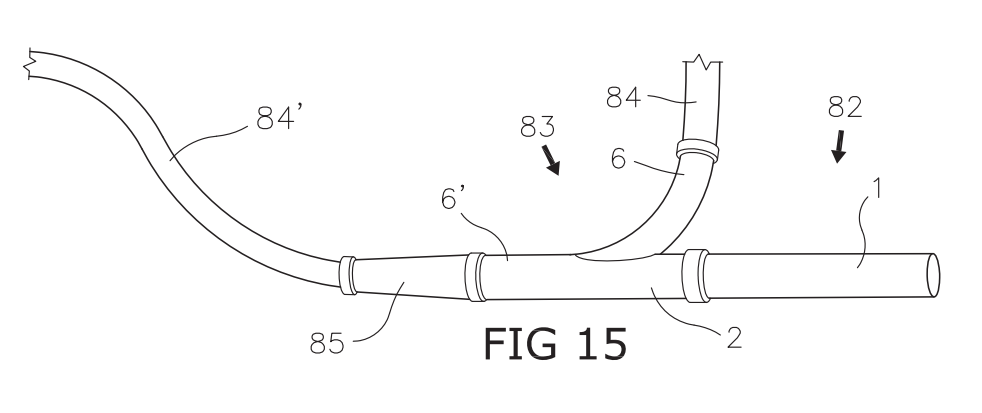

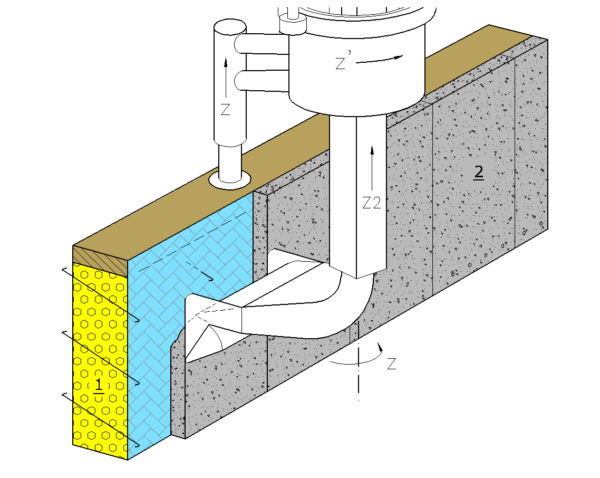

Inline Mixer System

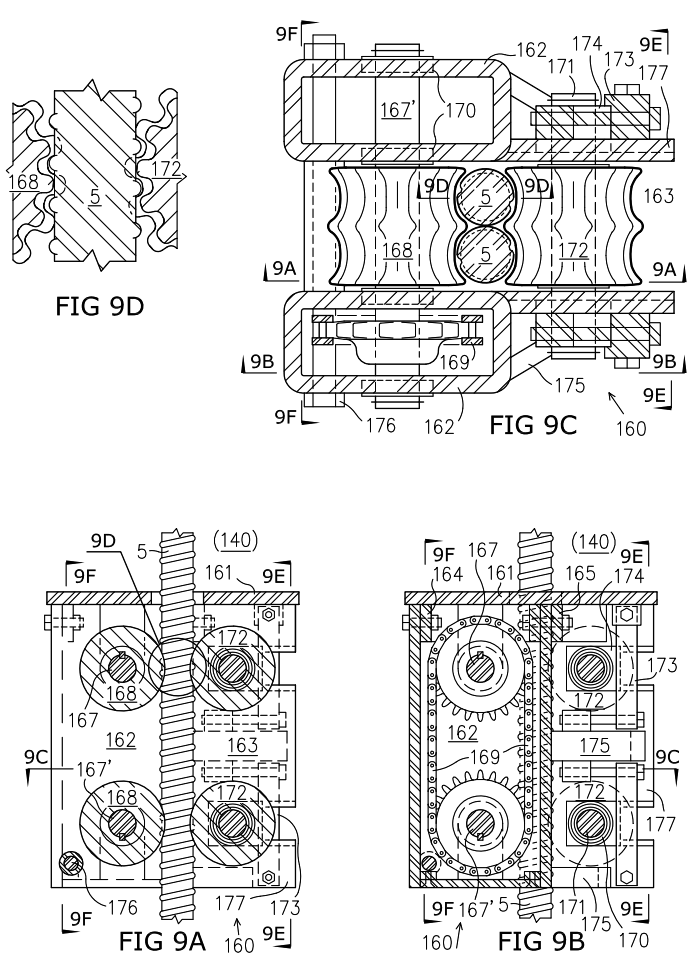

After a couple of big failures, we came up with an inline mixer that works extremely well with concrete. It passes aggregate without blocking, and it intermixes concrete and admix better than expected. The adjustable vanes are aligned, sloped, and oriented to maximize admix intermixing, with minimal aggregate obstruction. The projection is adjustable, to allow for different size aggregates. The admix dose rate is proportional to the concrete pump rate. Many variations of this will work and are disclosed. Most of our test projects used a simple paint pump (airless) and we dialed in pump speed according to concrete stacking performance.

tightest control of vibration signal into the concrete.

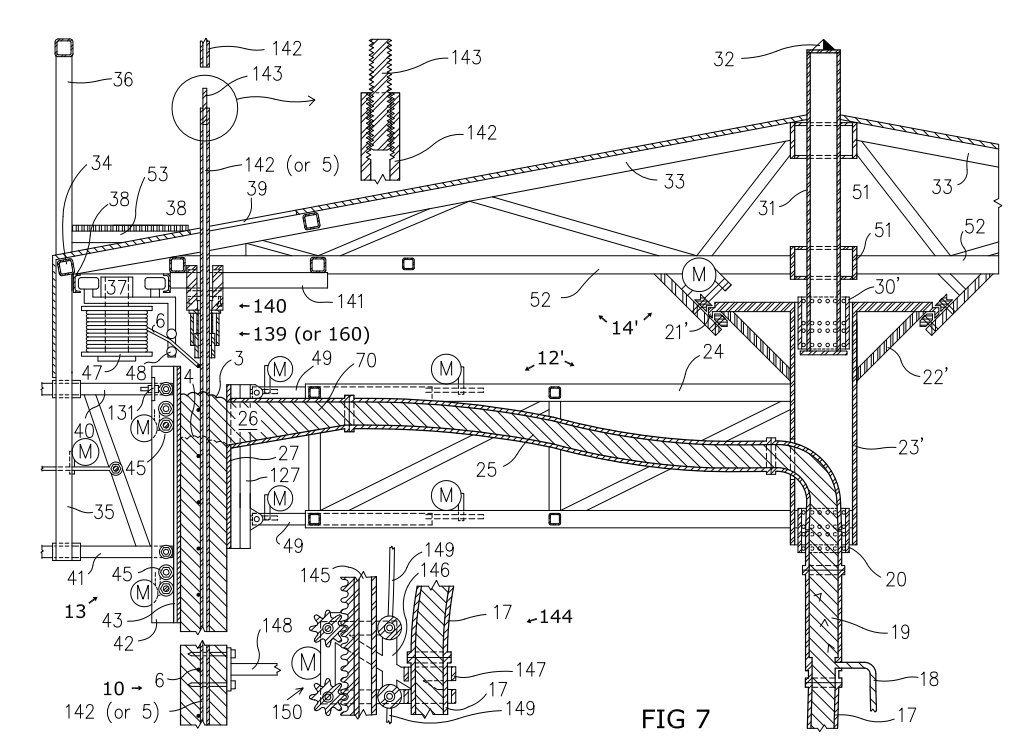

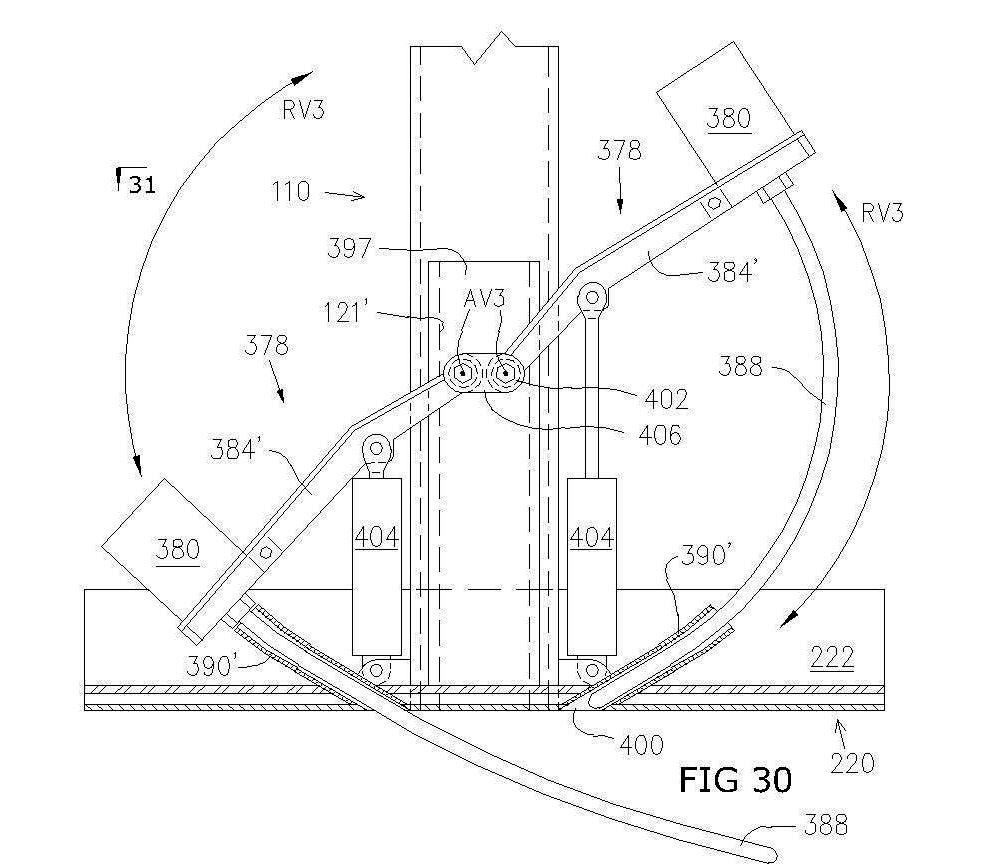

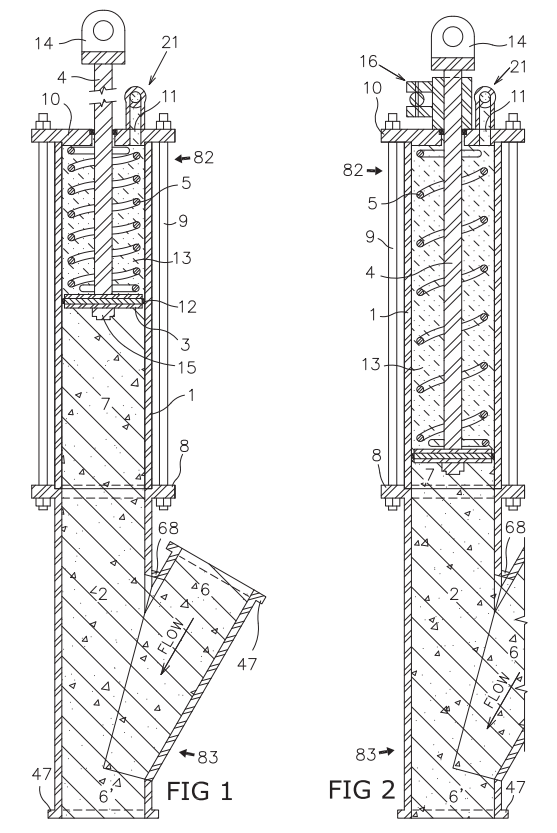

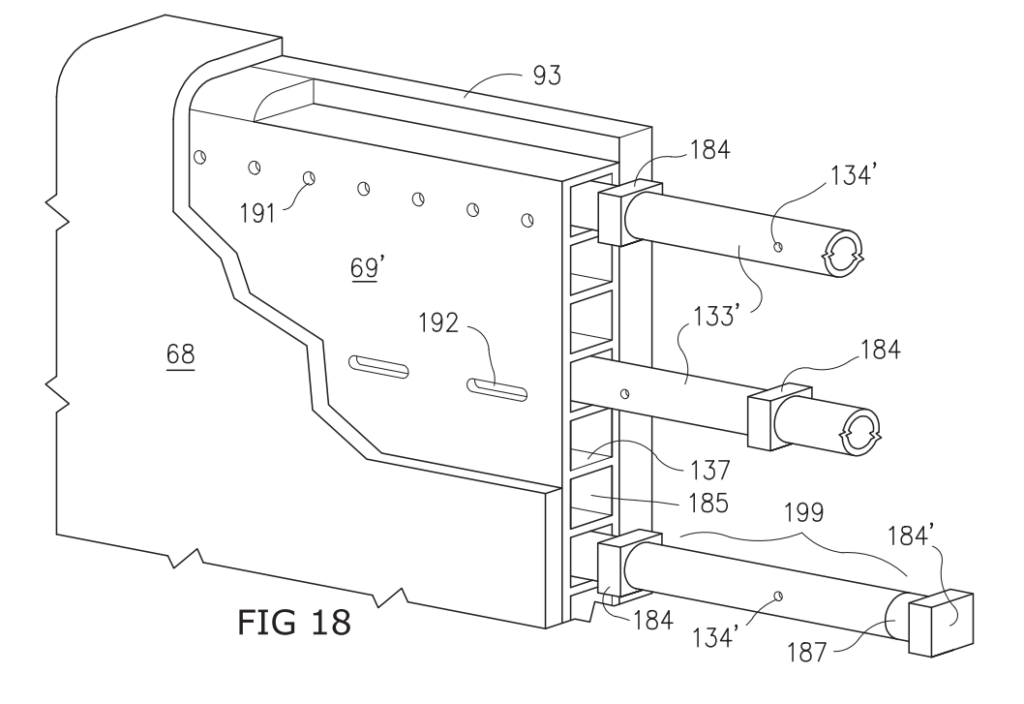

Articulating Screeder

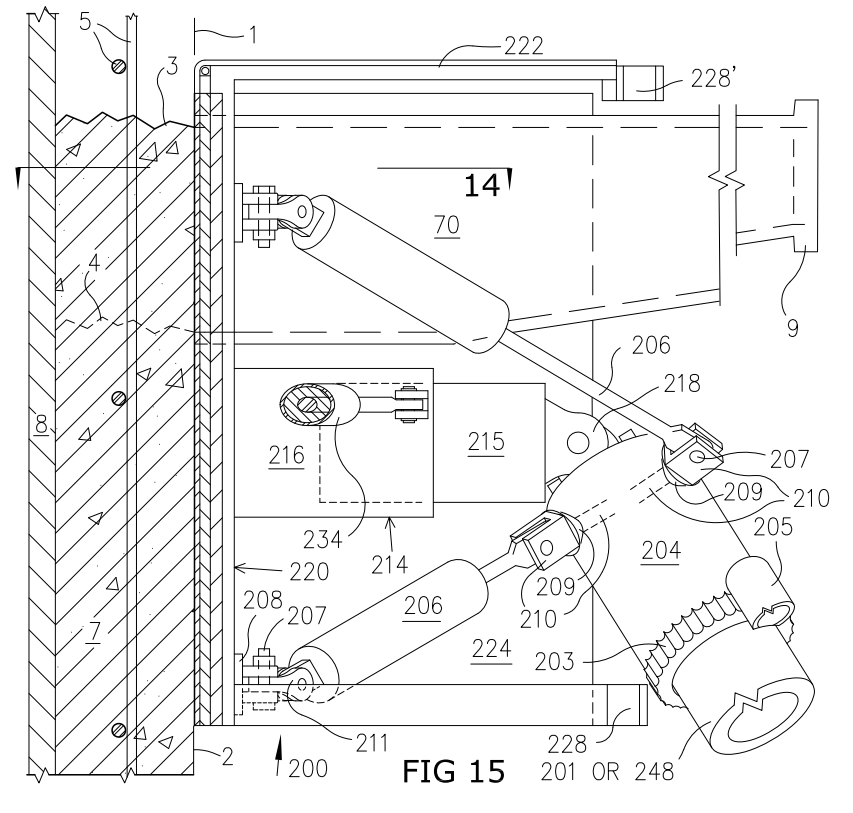

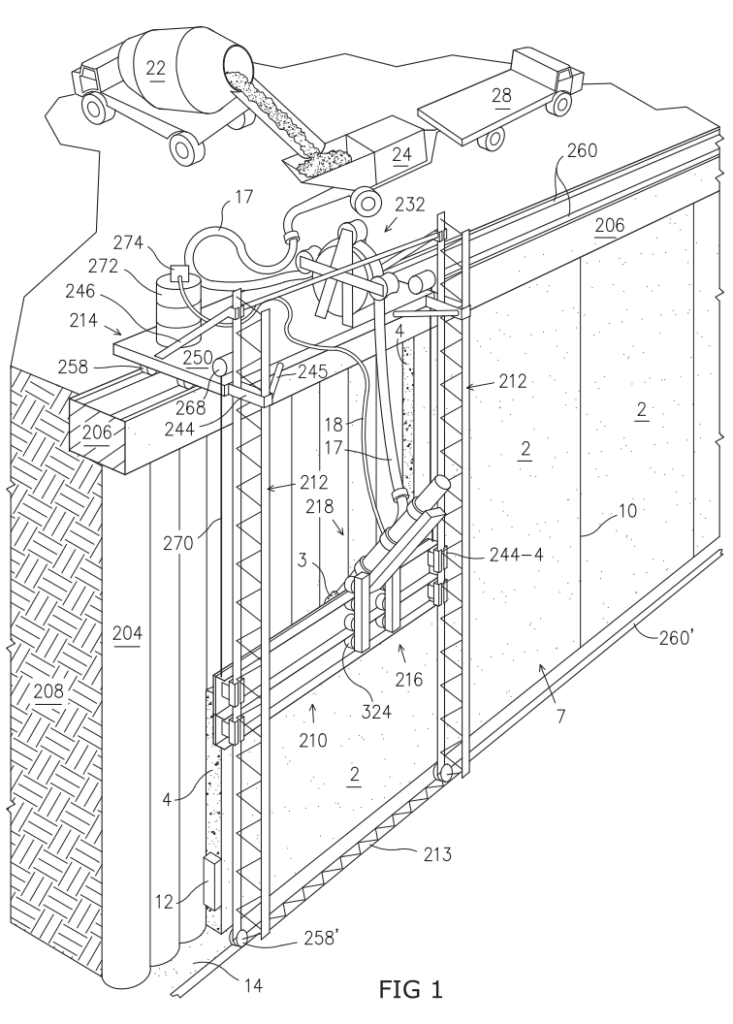

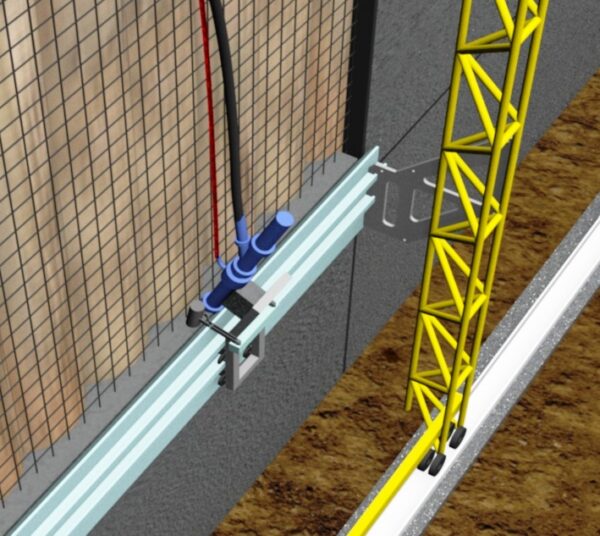

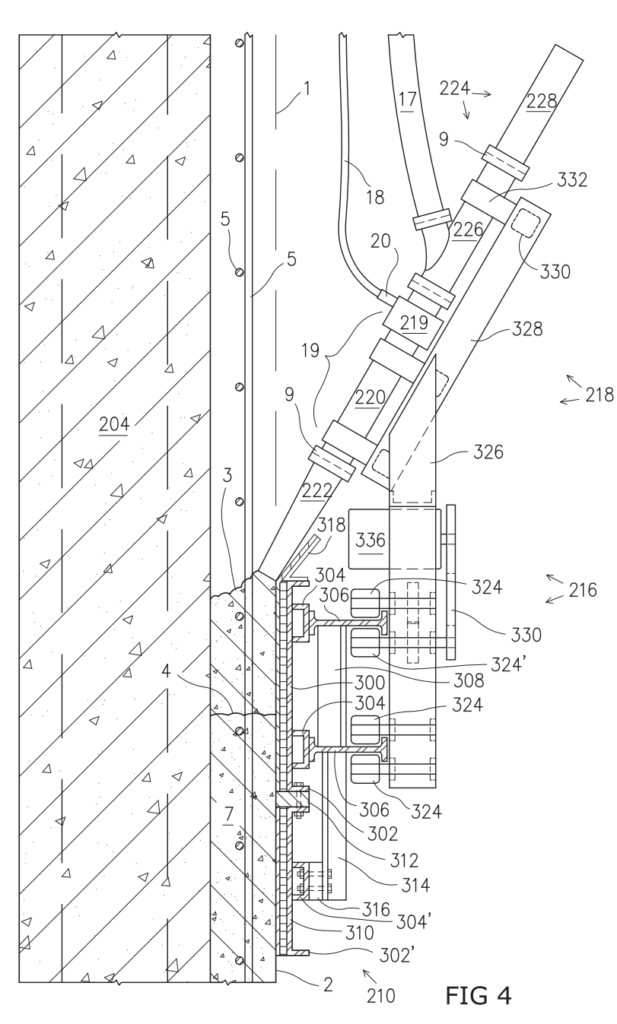

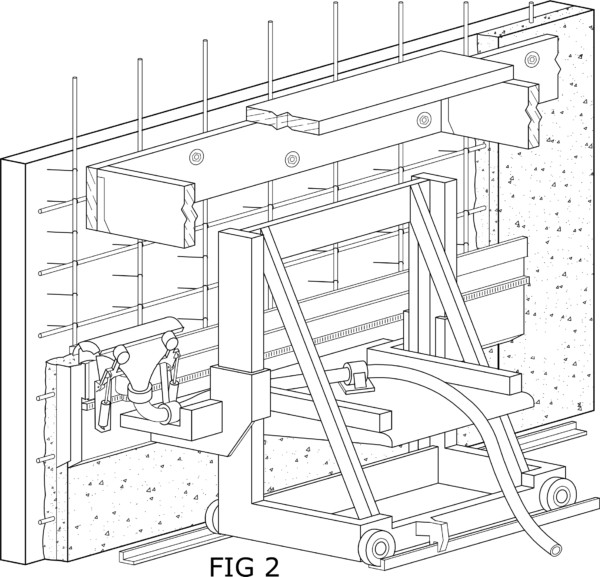

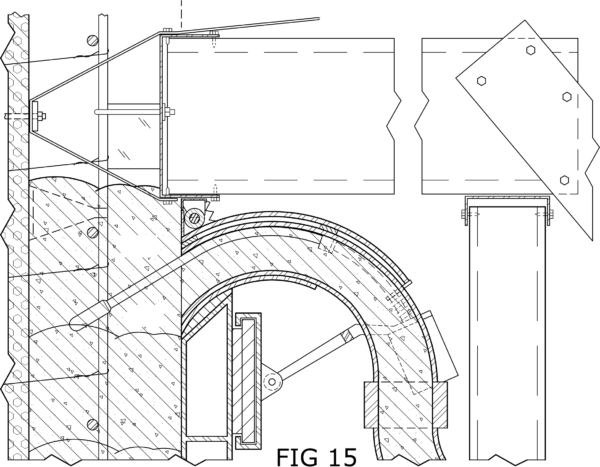

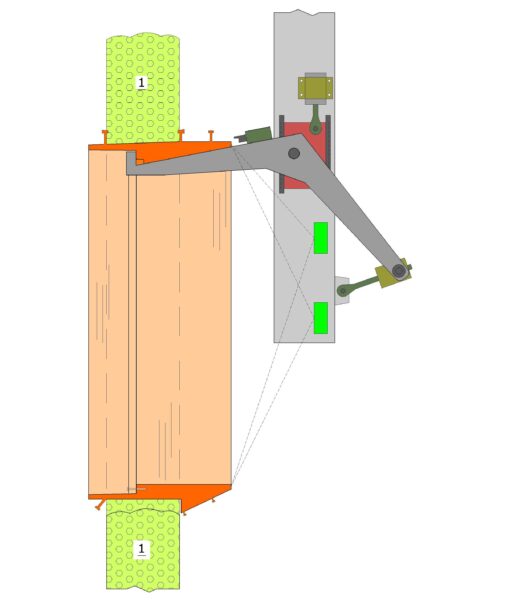

Placing concrete from one face of a wall by pumping the concrete through a face-plate, that is guided to define and screed a wall surface. This allows all normal, pre-positioned rebar, and the plate provides consolidation pressure. Of course this requires backing, which can be earth, insulating foam, or another guided plate – to build a freestanding wall. Depending on the mix design and type of admix, the concrete placement rate can depend on the consolidation rate, so efficient vibration is essential, but it cannot go below the plate. We emphasize the use of machine-controlled excavators, because that technology is in now use in construction, and excavators are built for jobsite conditions. Of course the screeder can also be robotically controlled, based on a digital model.

These images show secant-pile basement construction, where subsequent excavation leaves a crude surface that needs a concrete wall over it. Top and bottom tracks define the wall surface. Pumping the concrete is easy, if it can all be downhill.

The Big Screed

Most of our wall construction testing has been with a smaller and simpler variation of this method, as it can be low tech or high tech. Ideally, the slip-screed is autonomous, with pressure sensors indicating concrete consolidation, and so controlling the rate of pumping and nozzle travel. This way the people can avoid the hard, risky part. For most conditions, the vibration efficiency will control the placement rate. This system with the 3D-AdmixTM can build vertically as fast as most concrete pumps will pump.

This may take 10x longer?

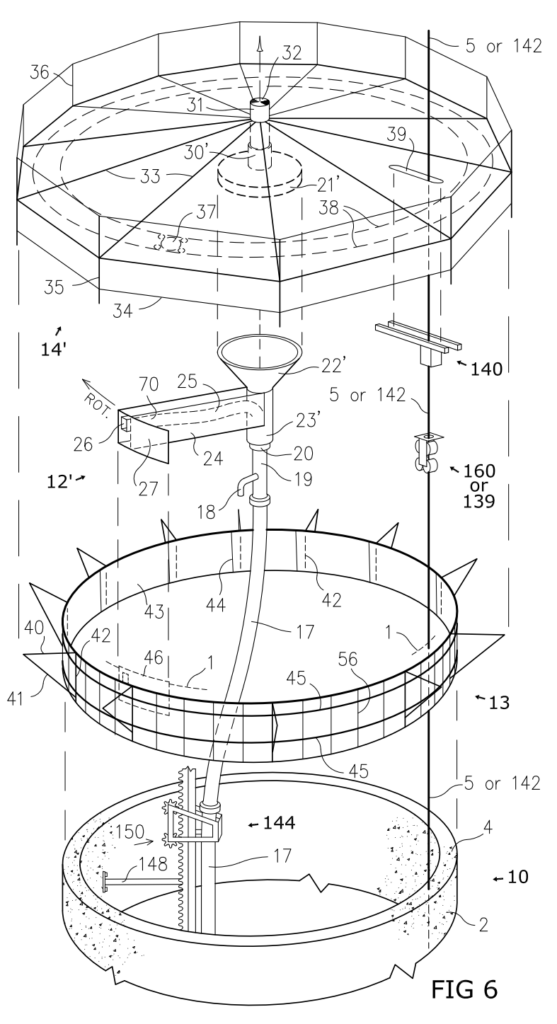

Wind Turbine Towers

At a million dollars a pop, the concrete version of these is the best. Some advocate 3D-printing these, but we feel that you gotta have the rebar for a tower. So instead of making the rebar a problem, we made it our friend. Because SpaceCrete allows such light slip-forming, you can use the rebar to climb the forms, and GPS to guide it. The more rebar, the better. This is more challenging for 3D printing.

The Rebar Climber

Concrete is pumped from the inside while tapered forms confine the outside. Cable spirals helically outside the vertical bars as the concrete placement progresses. The canopy protects. No crane is required until you set the nacelle. The height is limited only by how high you can pump concrete, and it can be extended by mounting a smaller steel tower over this.

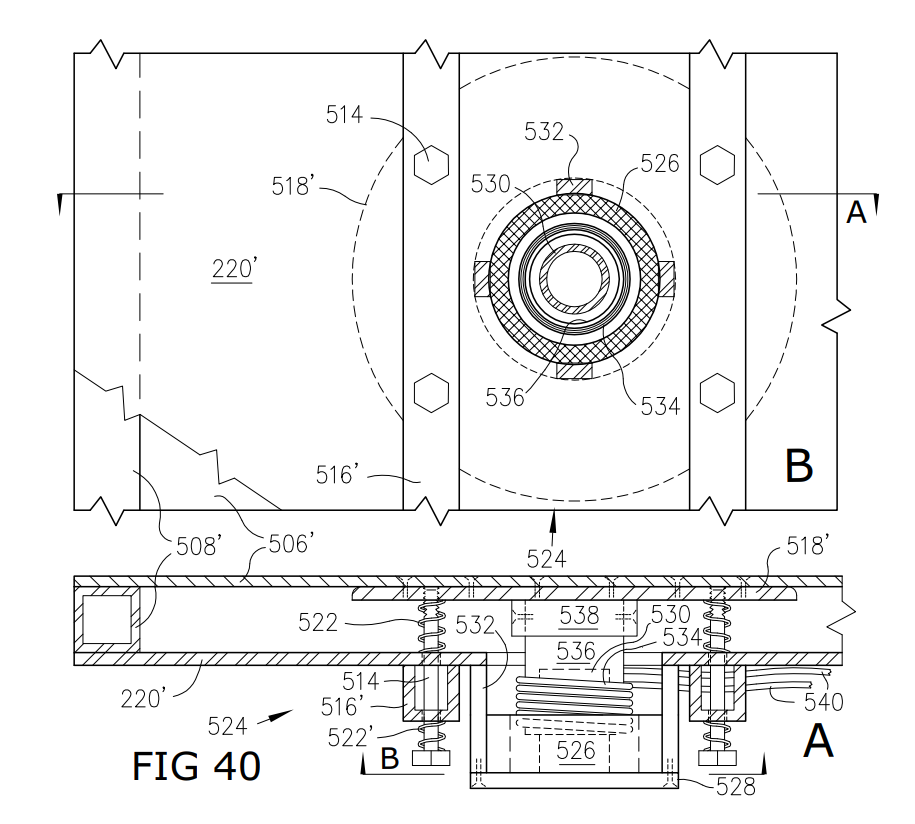

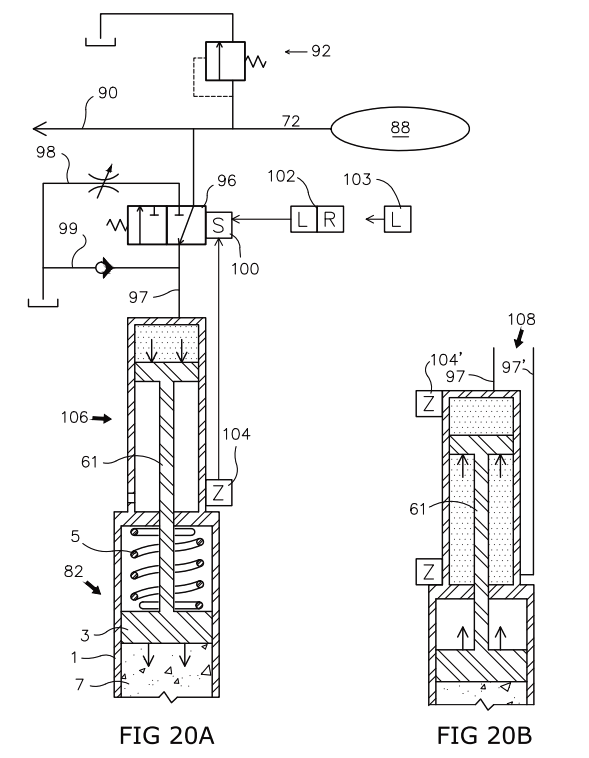

The Mudulatortm

All this autonomy needs assistance, if you are going to use a normal concrete pump. The standard swing-tube pump has extreme flow pulsations when switching pistons – not conducive to robotic placement. Existing surge suppressors are not good enough. So, we came up with some helpful improvements, by asking wye not.

By optimizing the flow geometry for a most-rapid

discharge, we were able to maximize pumping-gap

compensation with a passive device, and to allow

minimal inputs for an active device.

The Water Screed

We may have mentioned that thickened concrete is sticky. Every non-stick material we have tested sticks to the gelling concrete. It is a problem in screeding a smooth finished wall surface on the first pass – as is our goal. It appears that a sacrificial surface is a solution. As the screeding surface is not available to rewet regularly, we made one with a lubricating surface. The goal is to provide just the right amount of water to the concrete surface.

An early screed system on the first test wall of this building, as we move the screed for the next lift. This is delivered concrete, so repositioning needs to be fast and easy. It is now much improved over this version. Even with our crude methods, we can go one story high in eight minutes.

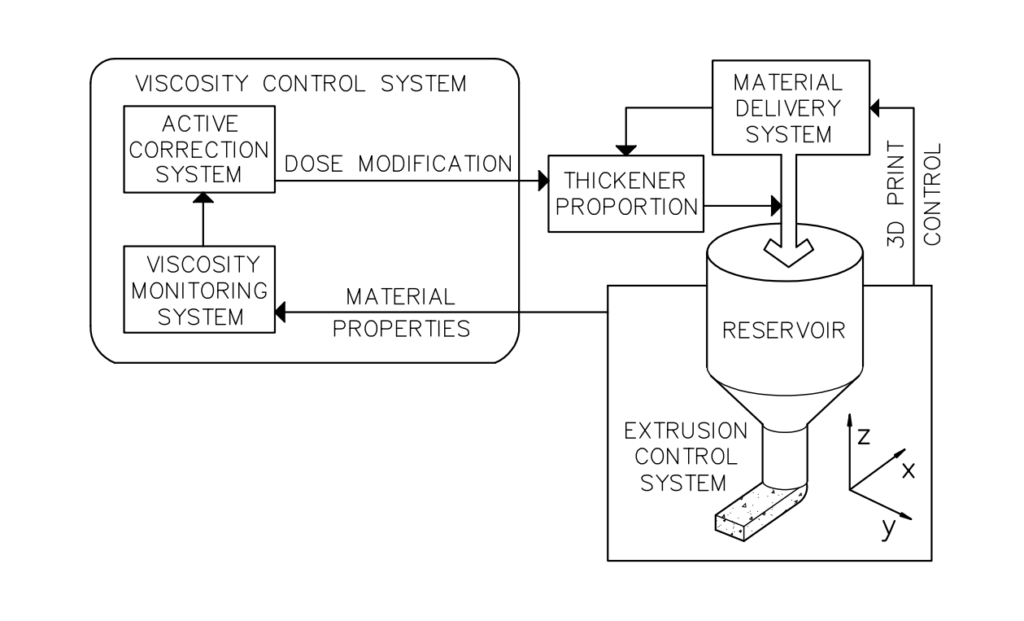

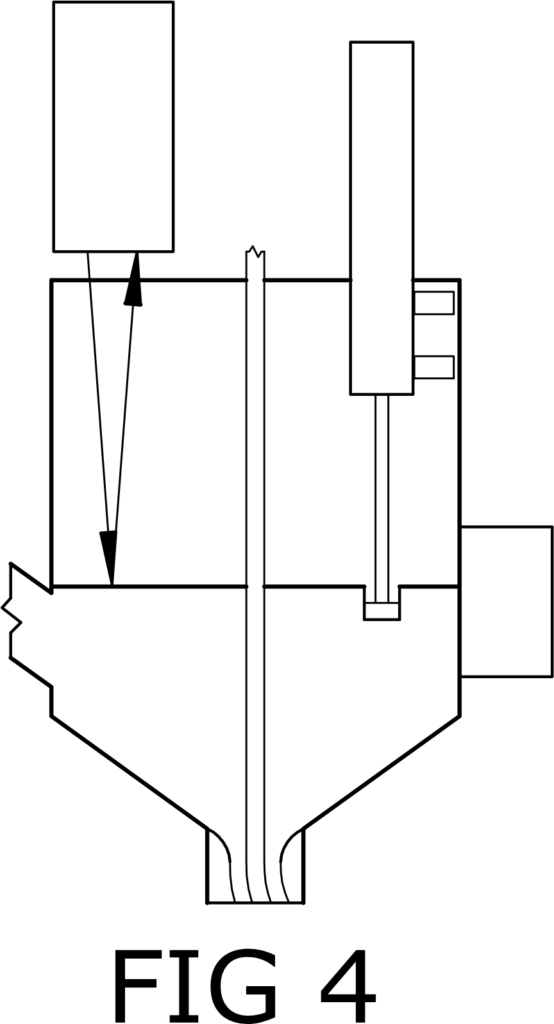

Rheology Control System

3D printing needs tight control of material rheology, but in changing conditions or with using native materials, constant adjustments can be required. So, if you have an admix that controls rheology by dose, why not have a system the monitors rheology and adjusts the dose, automatically? Rheology measurement can be made by conventional means or ultrasound, with instant feedback to the 3D-Admix dose rate.

|

|

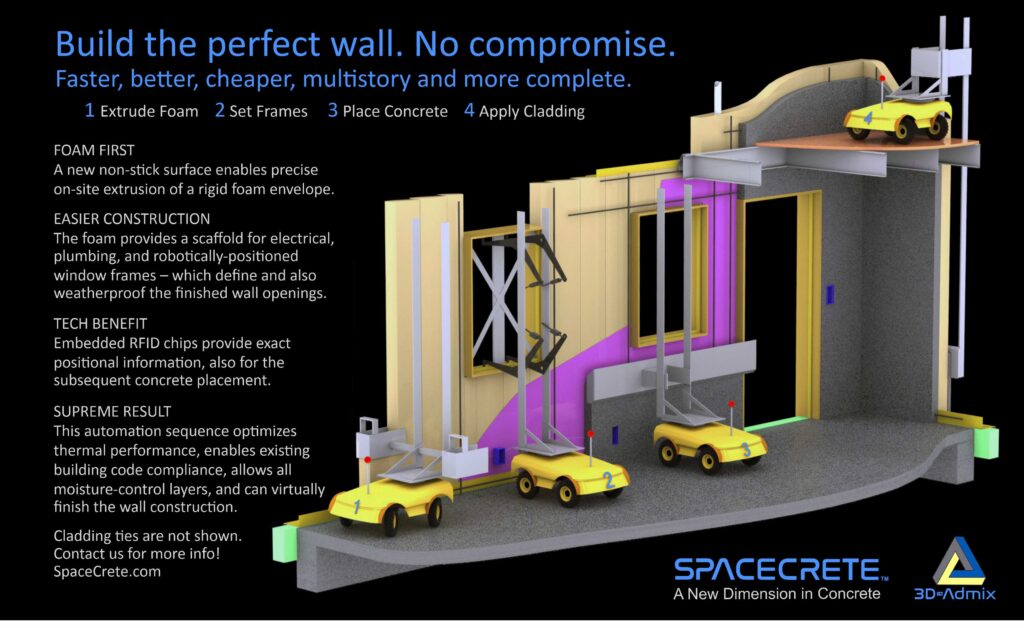

Digital Foam

A new type of non-stick surface allows the extrusion (or slip-forming) of the stickiest PU foam, so that rigid wall insulation can be custom “printed” onsite, with controlled, smooth, and flat surfaces. Foam formulations can be optimized for this application. A vertical motion works better, as gravity helps.

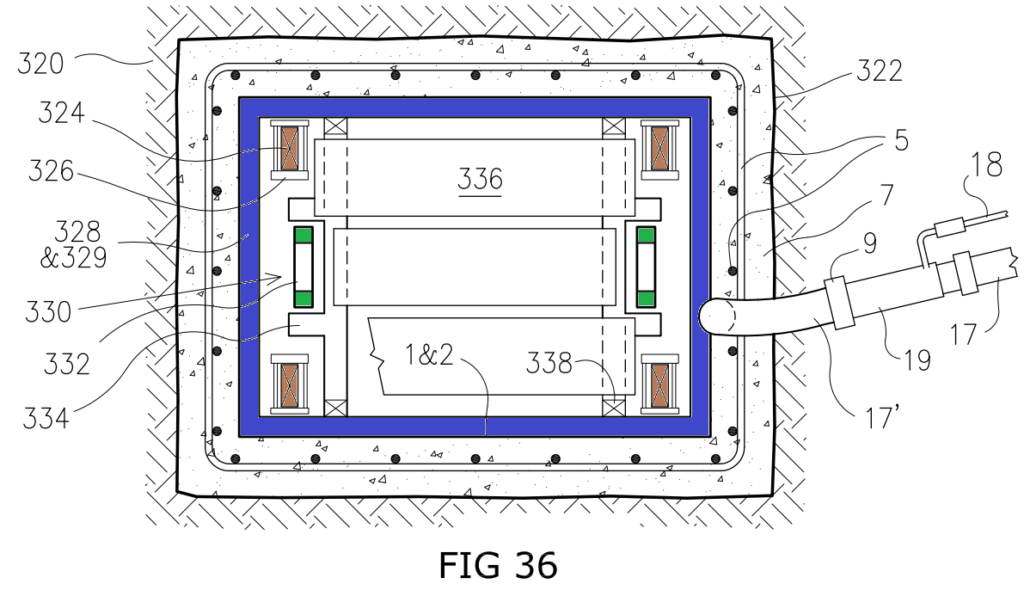

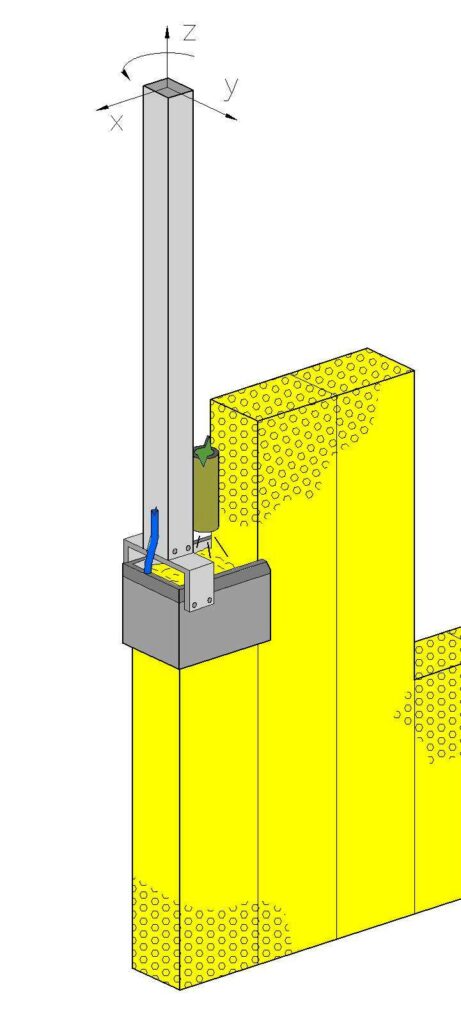

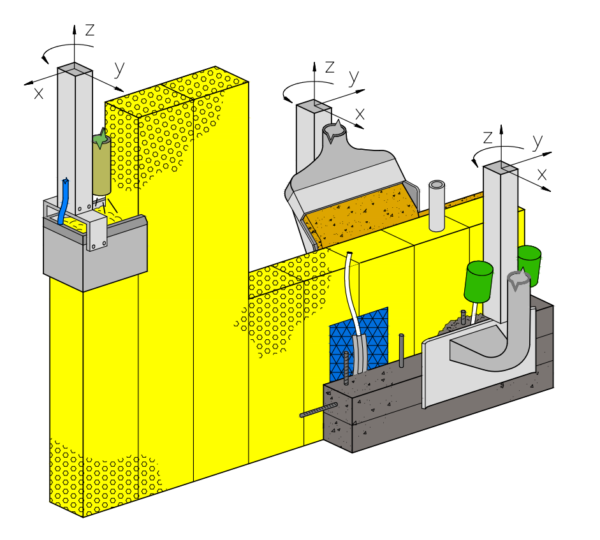

Compact Wall Machine

The idea is a concrete wall building machine that fits into tight spaces and places concrete flat against a backing surface, such as a plane of insulating foam or an excavation. Compact, so that it can work under bracing for a plane of rigid foam. Lightweight, so it can work on any floor of a multi-story building. A floor “skeleton” can brace the foam backing, where those connections double as seismic ties to the future floor diaphragm. Concrete fluid pressure, when vibrated, can be confined with magnets onto the rebar – which is tied to the outer reinforcing mesh, these connections doubling as cladding ties.

|

|

Way Better Wall Automation Sequence

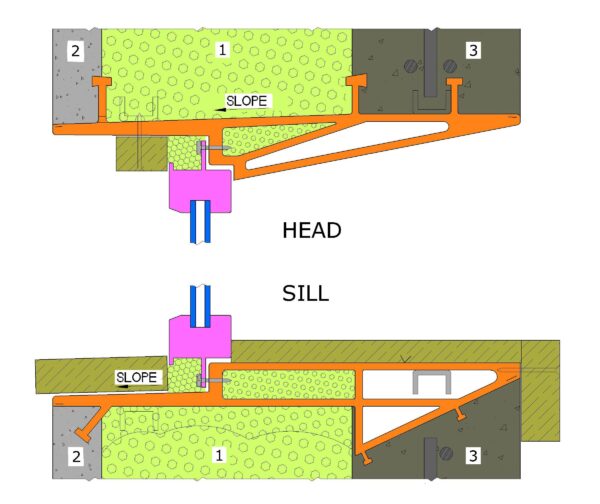

Printing insulation first vastly improves the automation of printed wall construction, because now you can install moisture control layers and avoid thermal bridging – which is huge, but especially because now you have physical support for electrical and window frames, before placing concrete, and you can foam around plumbing as you go.

Preplaced precise window frames remove most of the work otherwise required with 3D-printed window openings. They solve the problems of fitting windows to rough openings, waterproofing, truing the wall surfaces, and finishing the openings, because the precise frames take care of it all. The adjacent extruded pillars of foam hold each frame in position, in turn, so that robotic positioning is facilitated. RFID tags on each frame (and at other fixtures) tell the concrete and cladding placement systems where finished surfaces have edges. When the robots are done, the surfaces are done, and the windows can pop into precise receptacles. Electrical boxes are all in place, wired with romex, and can be easily inspected and revised, before concrete.

The huge advantage is that now you can meet all existing building codes for multi-story construction, in any seismic zone! Because the foam is already in place, the concrete can be placed from the side, against the foam, so any required reinforcing can now already be in place. This is the holy grail of construction 3D printing! In this case with the highest performing walls possible, as the wall structure doubles as super-insulated thermal mass, with fireproof cladding no thicker than necessary.

|

|

|

|

Links to Patent Drawings

Because of our tight budget, the patent applications have combined multiple inventions. They will need to be divided out later. Each of these applications represents several new ideas that should all be patentable. These 3 patent applications have all gone through the PCT (international) process. More patent applications have been filed, but they do not have formal drawings yet, so are not shown here. If you want more specific info about the status of any of our IP, or if only one idea looks interesting to you, please feel free to contact us. Thank you!

The Inline Mixer System is combined with the 3D-Admix (no drawings) and various means to build walls.

The Articulating Screeder and new vibrational systems is combined with Wind Turbine Towers and Rebar Climber hardware, etc.

Mudulator plus Big Screed filed.

Viscosity Monitoring and Control.

Improved Automation Sequence and New Nonstick Surface for Extrusions.

Portable Wall Machine.

New 3D-Admix™ composition (no drawings)