Real Concrete.

Easier. Better.

Faster.

Don’t Build Forms

Make Thinner Walls

Use Less Concrete

3D Print

Use Normal Rebar

Faster Slip Forming

Reduce CO2

Alternative Binders

Avoid Shotcrete

Save Cost

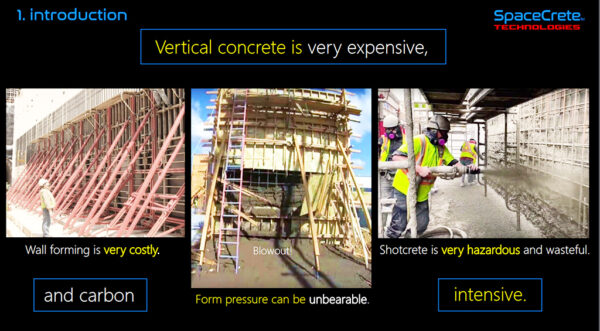

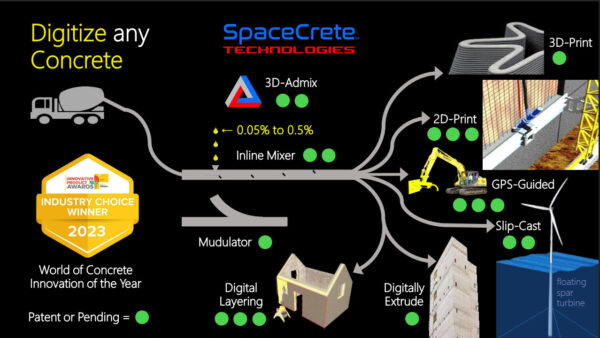

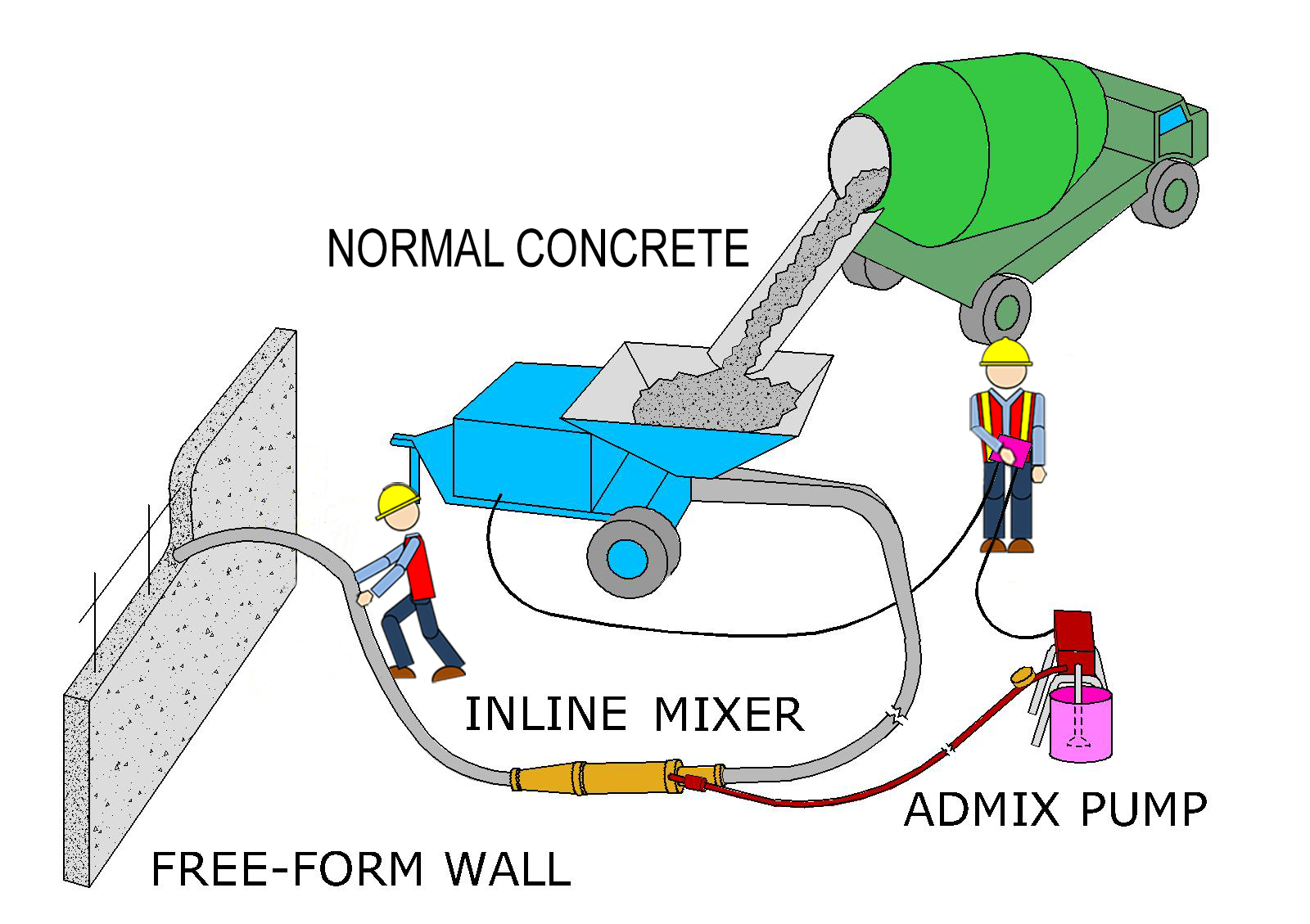

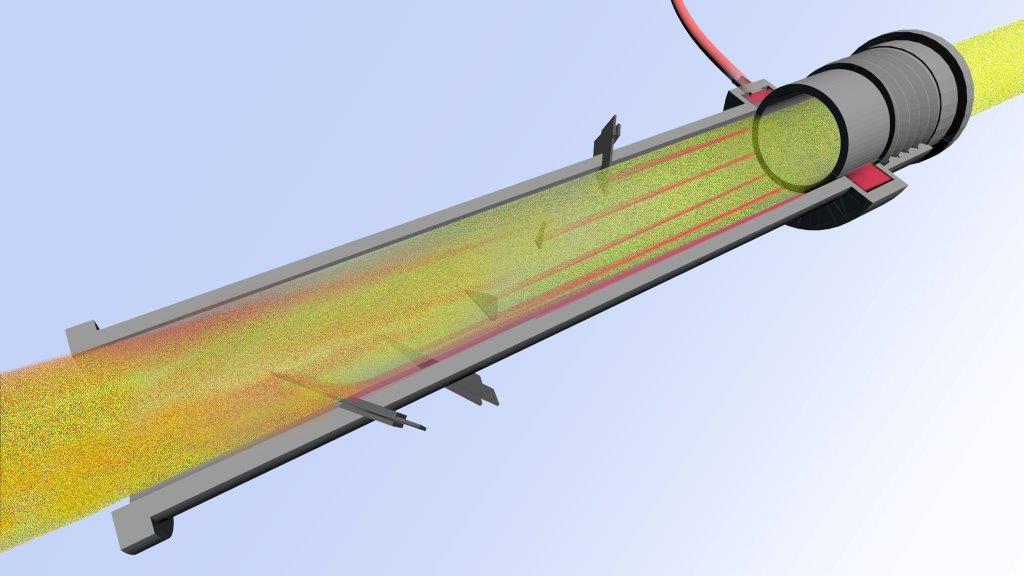

We have developed an admixture and inline-delivery system that allows 3D printing – or very rapid slip forming – with normal, delivered, pumpable concrete.

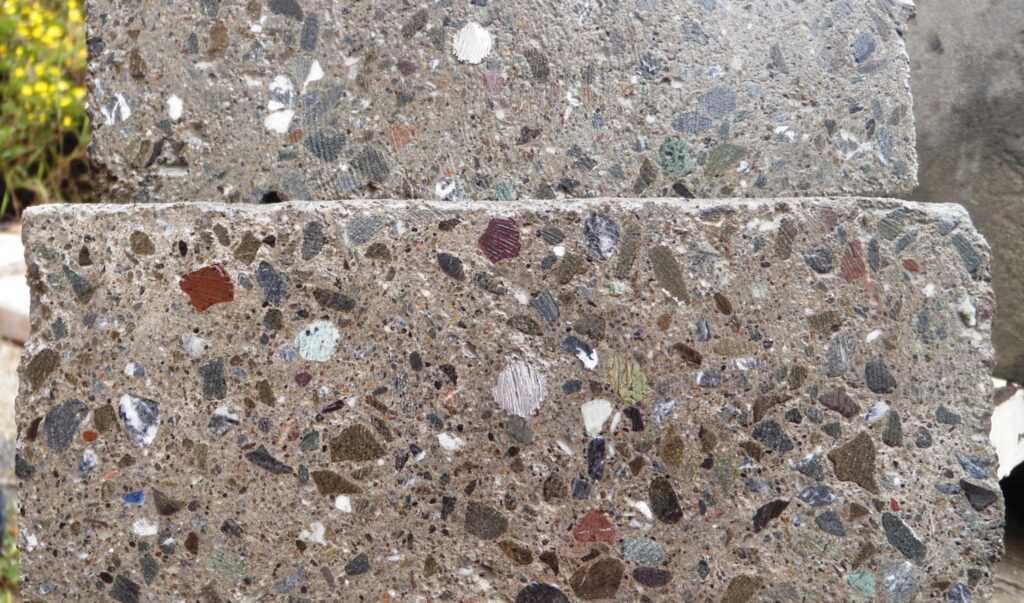

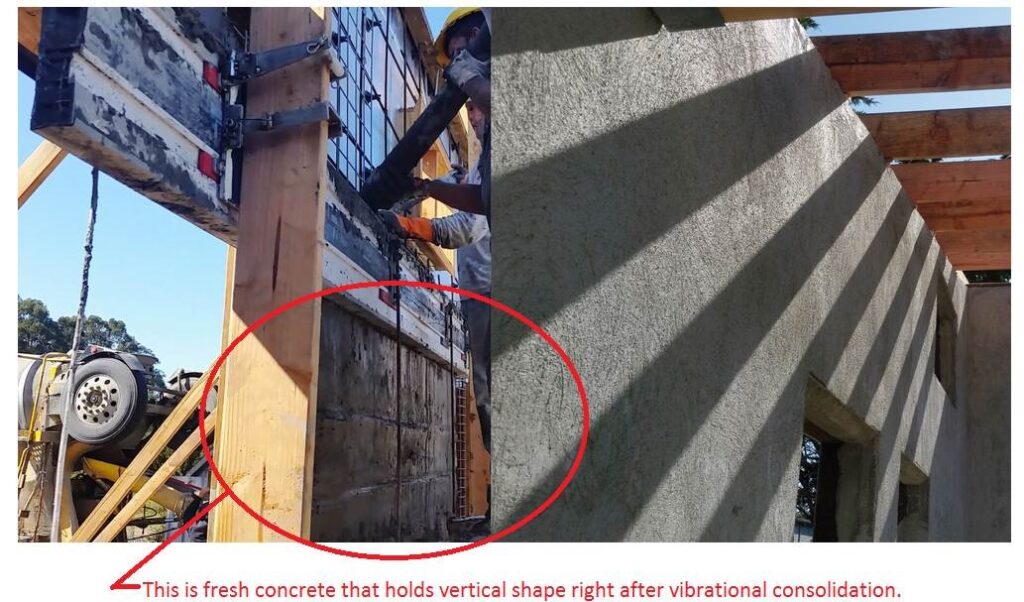

A SpaceCrete stacking demonstration. Normal concrete, no silica fume, no fibers. Link to actual video here.

“Digitally-controlled placement of concrete is our inevitable future.”

We work at the interface between machine control and finished concrete structure. We developed the admixture and delivery system that allows vertically-shaping fluid-concrete, rather than traditional forming. The vertical shape can be defined by simple or sophisticated construction hardware, or new technology – such as 3D printing, but using essentially normal concrete.

A Simple System

As SpaceCrete allows stacking pumped-concrete without forming, it opens up so many new ways to build with it. Your normal-delivered concrete can become 3D print material, with a very-low-dose of 3D-AdmixTM injected into the pump line. Or, you can vertically slip-form very rapidly, with pumpable concrete. The form pressure is gone the moment you stop vibrating it.

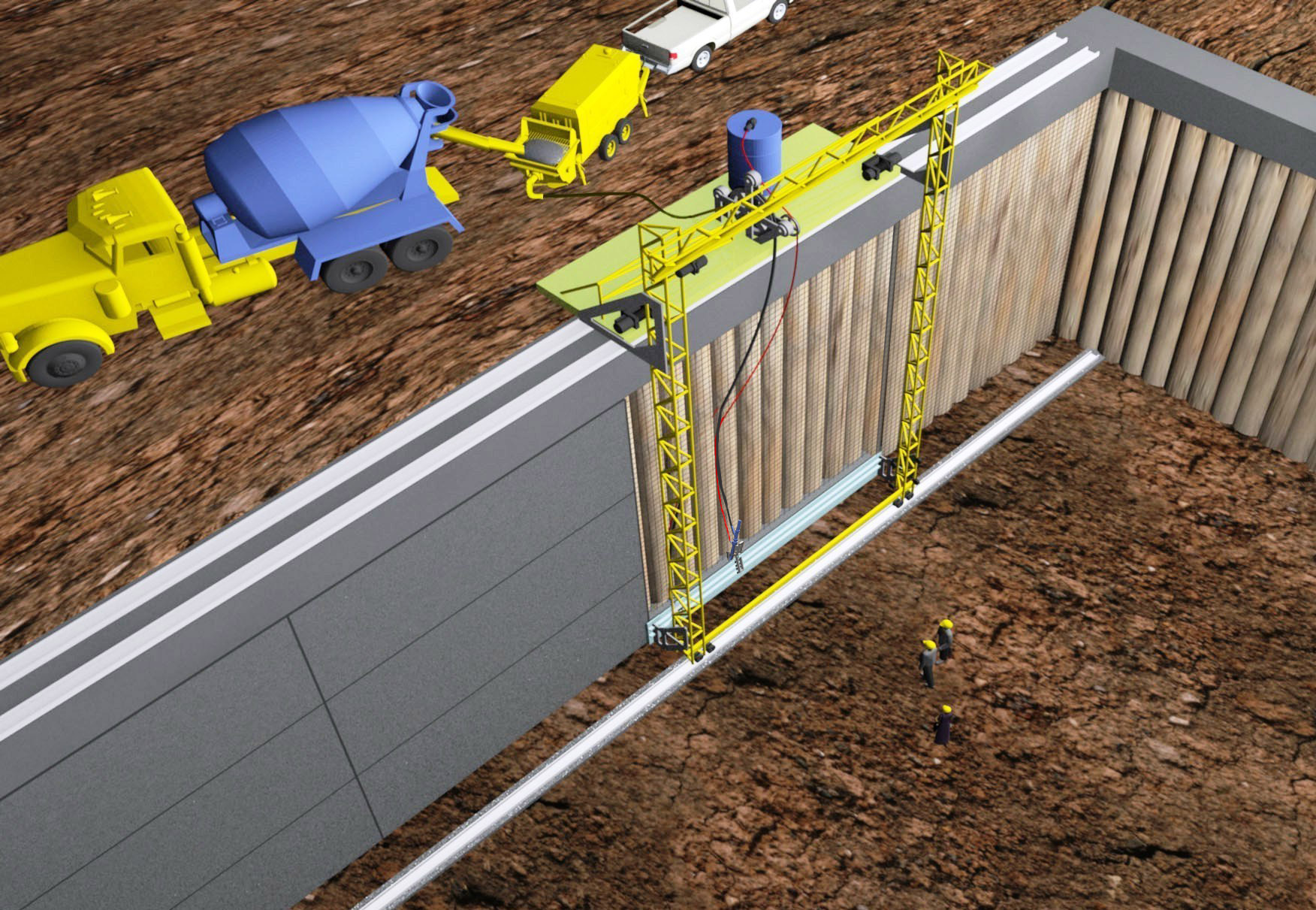

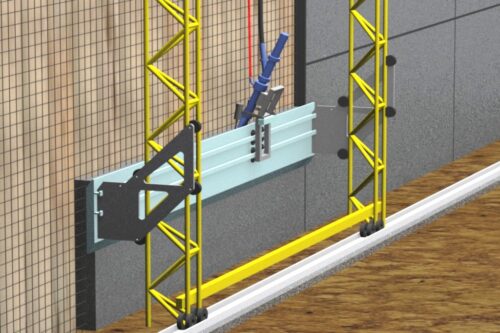

Rapid Slip Form

The Slipscreed can define a finished vertical plane of concrete as fast as you can pump it. Place solid concrete walls over rough excavations, insulating foam panels, or any vertical surface.

New Technology

Only 0.25% of 3D-AdmixTM transforms normal concrete into SpaceCrete. A 5” slump becomes zero slump inline – but with extreme shear thinning – so you can still pump it and work it as needed. Why build expensive forms? You can “create form” directly, or with digital control. Build Space, with conCrete

Excavator Attachment

Use machine-control to create a concrete retaining wall – easier, faster, more economically, and less hazardous than spraying shotcrete.

Machine-control is required!

Energy/Cost Efficient

Faster-Cheaper Slip-Forming

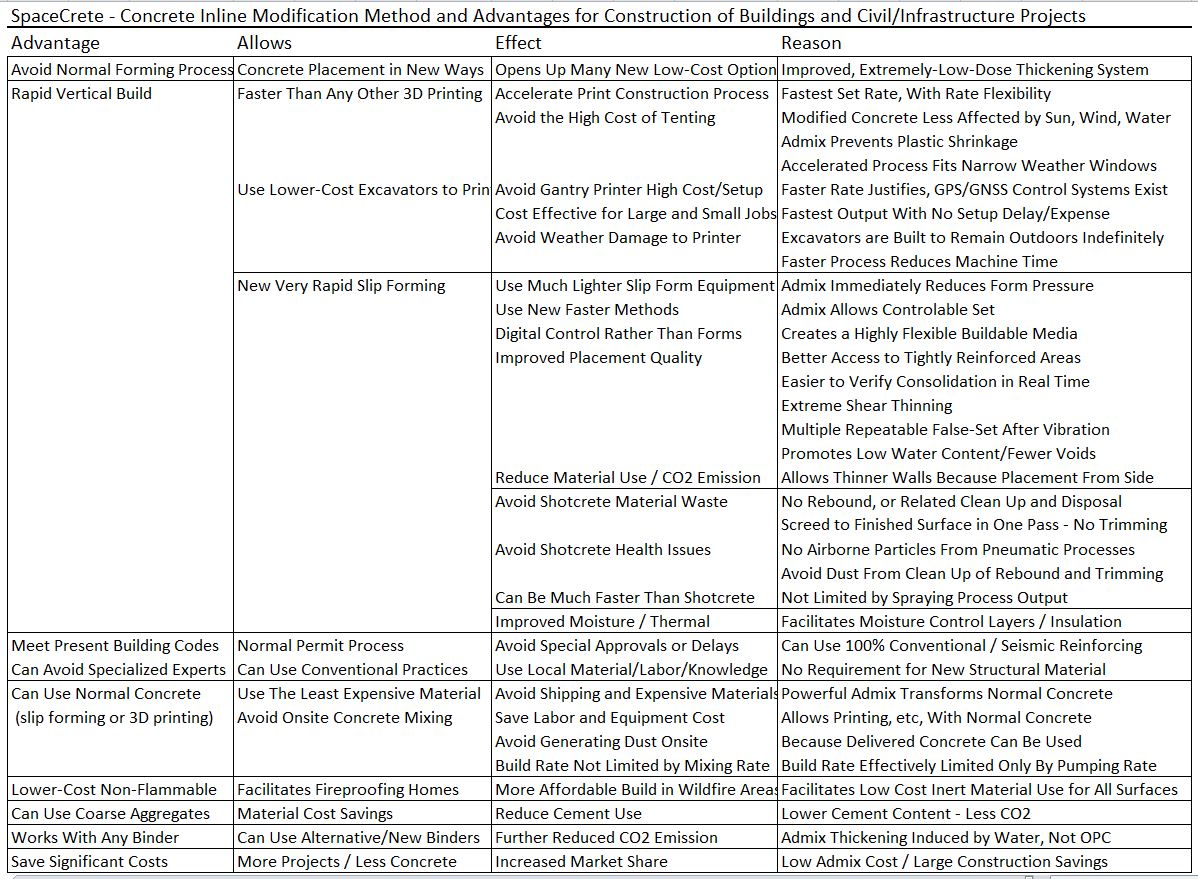

A Partial List of Benefits: